In urma scandalului generat in urma descoperirii faptului ca iPhone 6 se indoaie si iPhone 6 Plus se indoaie, compania Apple a publicat in cursul serii trecute un comunicat de presa in care anunta ca doar 9 clienti s-au plans de aceasta problema. Pentru ca un comunicat de presa nu este suficient, compania Apple a invitat jurnalistii americani in laboratorul in care testeaza rezistenta tuturor produselor ce urmeaza sa fie lansate pe piata.

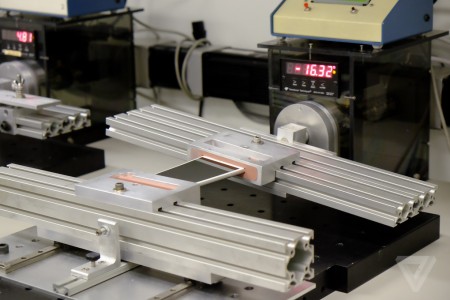

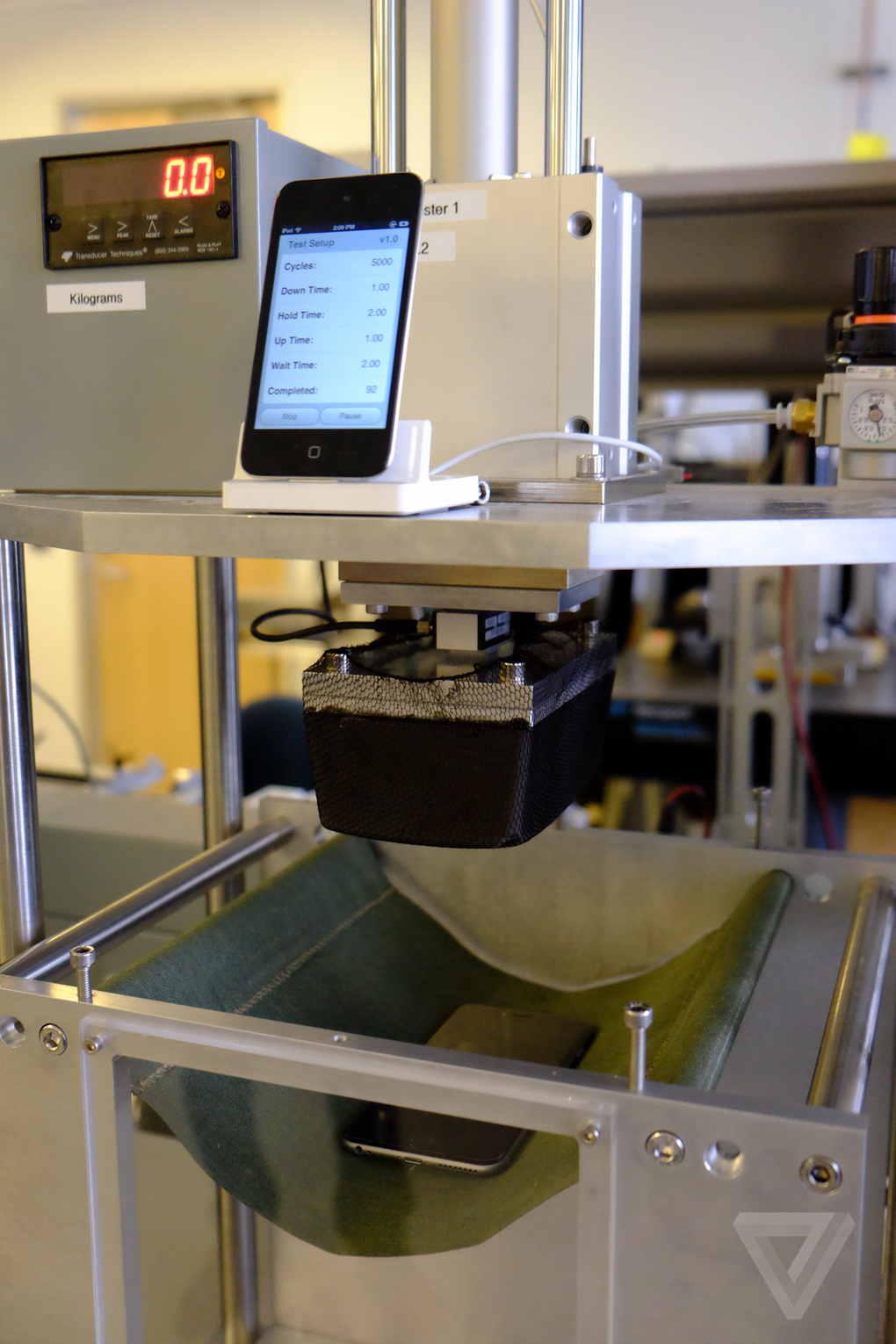

Turul laboratorului de testare a fost facut de catre Dan Riccio, vicepresedintele senior al diviziei hardware, iar acolo jurnalistii au putut vedea exact cum testeaza compania Apple fiecare produs care urmeaza sa fie lansat pe piata. Cu ajutorul masinilor din imagini, Apple indoaie si loveste produsele sale in orice mod posibil pentru a vedea cat de rezistente sunt ele in cazul loviturilor sau cazaturilor, corectand eventualele probleme inainte de a le lansa pe piata.

Apple sustine in continuare ca daca iPhone 6 se indoaie sau daca iPhone 6 Plus se indoaie, orice terminal poate fi dus la un Apple Store pentru a fi inspectat si inlocuit daca indoirea nu este cauzata de catre utilizator. Si in final, cele 5 metode de testare folosite de catre Apple :

- aplicarea de presiune in 3 puncte;

- To make sure new iPhones can handle “reasonable” force, Apple puts pressure on the device at three different points along the frame.

- aplicarea de presiune in diverse puncte cheie prin repetarea ciclurilor;

- The pressure-point cycling tests place “substantial” force across an iPhone’s display and encasing, while it is held along its edges, to ensure that an iPhone can be bent and pushed many times over during its lifespan. Apple runs this test hundreds of times to ensure durability.

- test de torsiune;

- The iPhone is twisted and turned like a piece of licorice about 8,000 times. “The company does this to make sure its devices can handle twists and torque in various situations, such as sitting on an iPhone unevenly.”

- teste de asezare pe terminale;

- An engineer sits down thousands of times with the iPhone pocketed in every position imaginable. What a job.

- si in final studiile facute in lumea reala cu utilizatori.

- First was the “sit test.” Dan Riccio, Apple’s senior vice president of hardware engineering, says this test is the one that is most relevant for customers with concerns about the phones bending in pockets. There are three parts to the sit test. The first part simulates a typical user sitting down on a hard surface, the second simulates someone sinking into something softer like a couch, and finally there’s what Riccio calls a “worst-case” tests, where someone would have a phone in their pocket and sit down on a hard surface at an angle.

Three-point bending: Apple’s tests place pressure on iPhones in varying degrees to make sure they can handle “reasonable” force in various situations.

Pressure-point cycling: The pressure-point cycling tests place “substantial” force across an iPhone’s display and encasing, while it is held along its edges, to ensure that an iPhone can be bent and pushed many times over during its lifespan. Apple runs this test hundreds of times to ensure durability.

Torsion testing: Apple clamps down an iPhone at both ends and twists the handset about 8,000 times. The company does this to make sure its devices can handle twists and torque in various situations, such as sitting on an iPhone unevenly.

Sit tests: A single phone is placed into simulations reflecting real-life scenarios, such as being in the back pocket of tight jeans. Phones are sat on, against a hard surface, thousands of times and in multiple positions in a pocket. Sit tests cover both orientations of the glass screen—facing out and facing in.

Real-life user studies: Another part of testing involves real humans, hundreds of company employees live with and use the phones in various situations to test for both durability and performance. Employees who have the highest usage rates on their phones are selected to take part, and Apple methodically checks the phones for any issues as they’re being used.